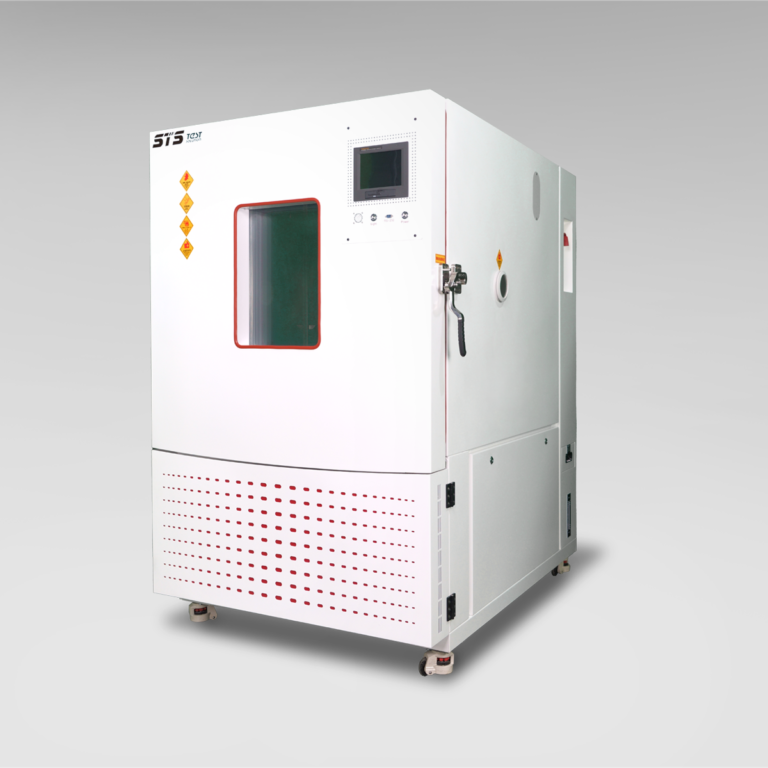

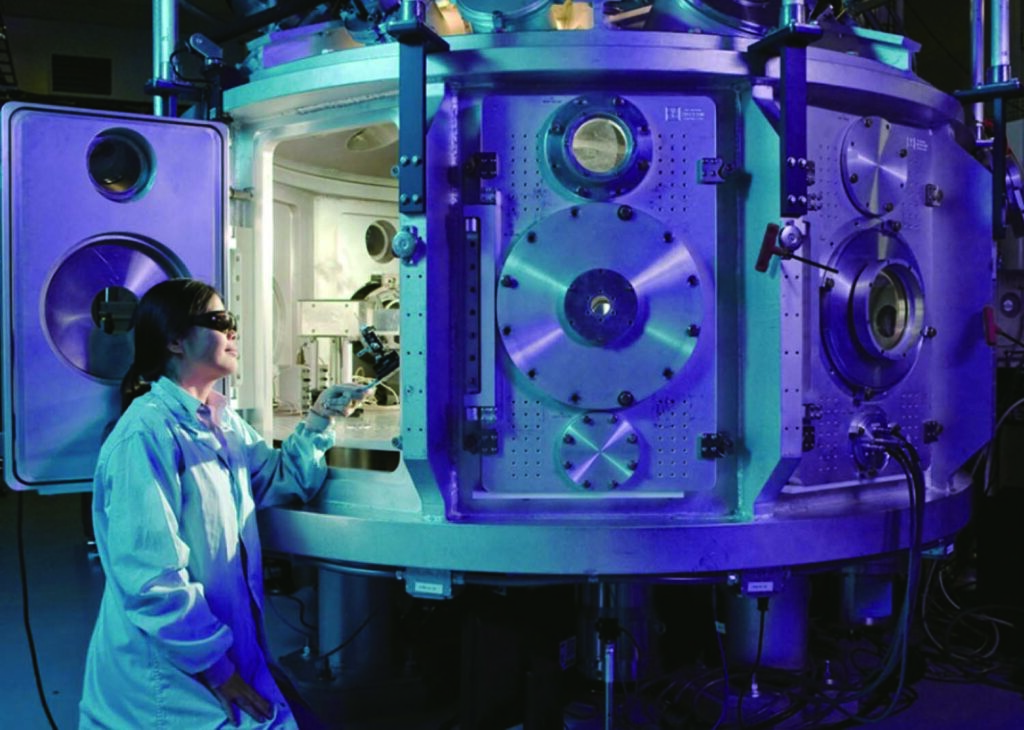

Climatic Temperature Humidity Test Chamber is one model test chamber which could simulate daily temperature and humidity environment. As we all know, most of products need to test operating performances in various daily environments. After this test, most of products could be sold with a qualified label. And this model test chamber could be used for most industrial products

Electroplate baking paint metal outer shell

The outer shells of the test chamber are assembled by electroplate baking paint sheet metal, which could make the appearance beautiful and compact

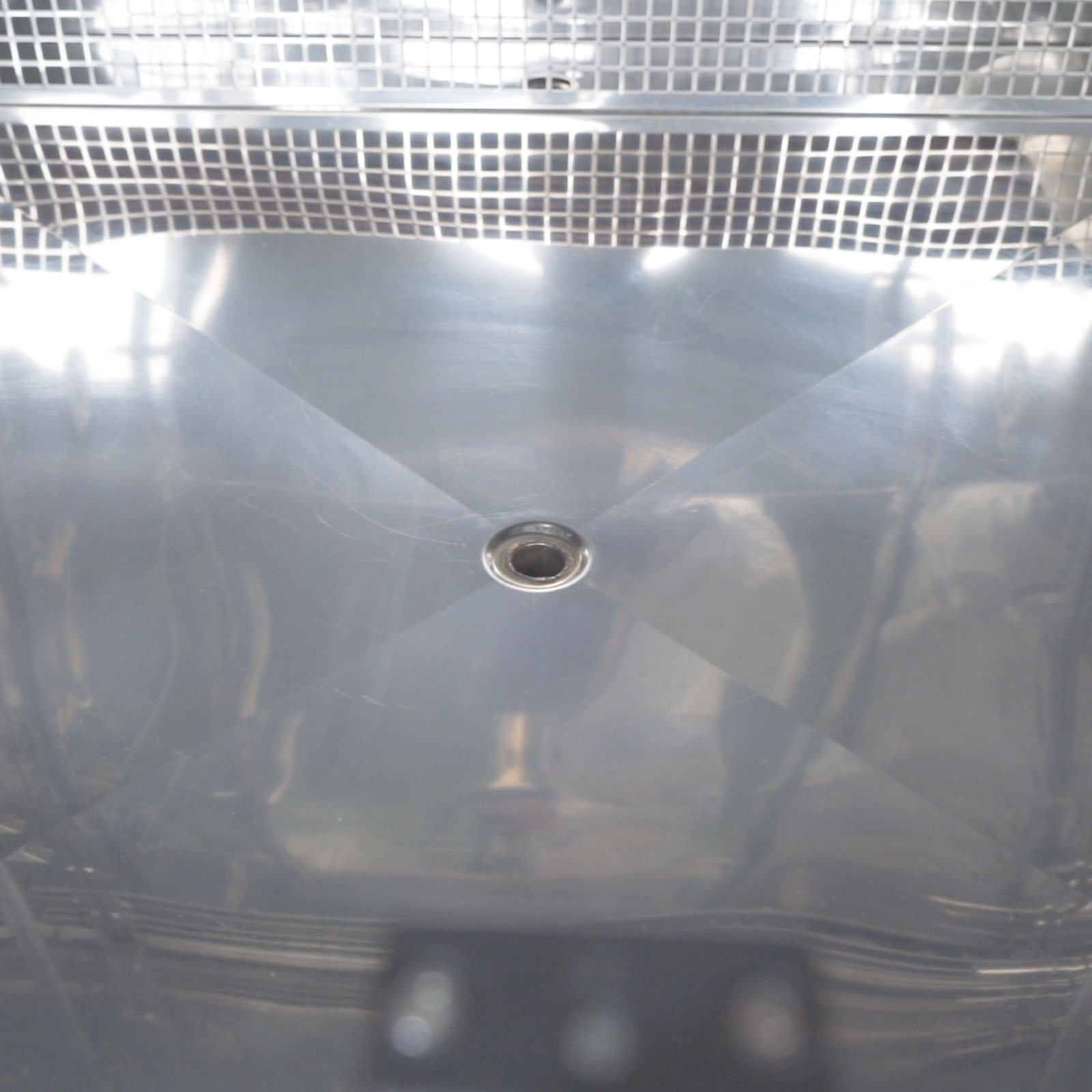

Stainless steel material inner test space

SUS#304,316 material optional,basically SUS#304 material

Single door on the left

The door of the test chamber is designed on the left and locked on the right, which fulfill the industry habits and user habits

Observation window

3 layers of vacuum glass for heat and sweat prevention; door frame electric heating (automatic adjustment) anti-frost, anti-condensation device; so that you can at any time through the observation window clearly observe the test status of the samples tested in the box.

One deflector channel and 3 deflector ports

One deflector channel on the interior bottom of the upper door, one deflector hole on the interior top of the lower door, and 2 deflector holes on the bottom of the test space, which could drain residual water to ensure the test space clean.

Controller

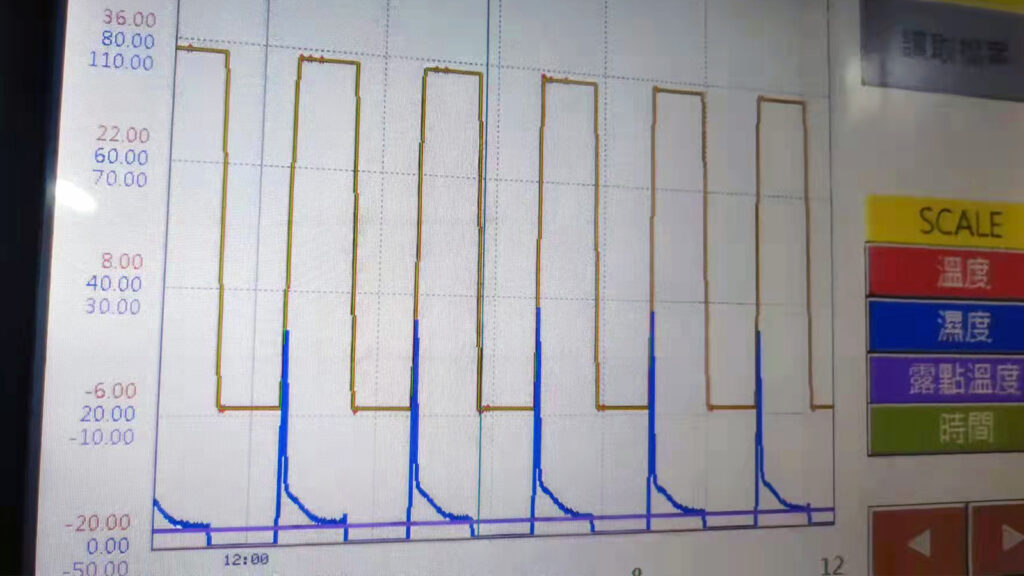

Climatic test chamber installed with full-color touch screen works in concert with your devices for real-time observations and management. Programmable operating controller with PID+SSR/SCR automatic positive and backward synchronous output

1.Temperature Measuring System:

Climatic test chamber could simulate ambient temperature from -70℃ to +180℃, so it could test most of products quality stability when the ambient temperature changes. From extremely cold to extra high temperature, climatic test chamber could fit most industries or some special products need to bear extremely temperature. The temperature range is optional

2.Humidity Measuring System:

Climatic test chamber could simulate ambient humidity from 10%RH to 98%RH, so it could test most of products quality stability when the ambient humidity changes. From extremely drought to extra wet, climatic test chamber could fit most industries or some special products need to bear extremely humidity. The humidity range is optional

Preparations before starting up:

A. Do not operate the chamber before the chamberis installed.

B. Operators should read user manual and its accessories carefully before operating test chamber.

C. Before operating the chamber, close the test chamber door and confirm only test specimen in the test chamber; when opening the door, make sure test chamber has stopped and the inner temperature is close to ambient.

D. Before running, you must first check whether the set value of the overtemperature protection of the chamber matches the maximum allowed temperature of the test sample.

E. Confirm that the water supply valve and the drain valve are open (for water-cooled equipment).

F. All specimens must be tightly fixed to prevent the specimens from scattering inside the test area to ensure the test space is clean.

G. Confirm that the test samples have been placed and the chamber doors are closed;

H. Set the temperature and humidity and run the test chamber

List of Dangerous Goods

Spontaneous combustion, flammable, explosive, volatile, corrosive, radioactive, strongly oxidizing, dust-generating substances (objects), highly toxic chemicals, toxic microorganisms (viruses), etc., or test items containing these components, or the tested item may produce these components during testing/storage.

Do not put the test items mentioned above into the test box (lab) for testing or storage!

A. Do not open the door of the laboratory at low temperatures to prevent damage to the door sealing tape, and prevent the fan shaft from freezing at low temperature.

B. Try to avoid artificially stopping and starting the compressor repeatedly in a short time (3 minutes), such as starting immediately after stopping, which will reduce the service life of the compressor.

C. When the test chamber is working, do not touch the exposed pipes of the refrigerator arbitrarily to avoid burns or frostbite; Do not open the test area door immediately after finishing the test work to avoid burns or frostbite; When removing the test product from the equipment box, gloves must be worn to avoid burns or frostbite.

D. In winter, ensure that the indoor temperature is not lower than 0 ° C, otherwise the refrigerating system may be damaged.

E. In order to ensure the normal supply of cooling water, it is recommended to clean the cooling water filter of the refrigerator every 30 days or so.

F. Use a dry cloth to clean up the water in the drain pan of the suction and freezing unit once a month

A. After the control system is powered on, the controller enters the self-test state; Do not press any key of the controller before the self-test is completed, otherwise the control parameters will be lost and the device will not operate normally.

B. After reattaching the power cord for unpredictable reasons, be sure to verify that the controller’s power supply voltage is the same as the power supply voltage before turning on the power.

C. Do not place magnetic objects near the controller, and do not install the device near a source with a strong electromagnetic field, otherwise it will adversely affect the controller.

D. Turn off the power when the device is not used for a long time.

E. In order to extend the service life of the panel, it is recommended to use the screen saver function when the control panel is not operated for a long time.

F. If the monitor works in a high temperature environment for a long time, it will shorten the life of the LCD and reduce the quality of the screen display. In the case of high temperature (≥40 ℃), it is recommended to adjust the contrast of the LCD

As we all know, each product need to pass various examinations to fulfill qualified standard before selling, so it is important to determine your testing requirements for choosing fittable climatic test chamber. There are some test requirements are for your reference:

A. Test Specimen Industry, for example, The Automobile Industry.

B. Fulfilled Test Standards, for example, IEC60364 test standards.

C. Test Conditions Range, for example, temperature & humidity range.

D. Test Space Capacity, for example, some large test specimen need enough space to put

When you plan to purchase one climatic test chamber, you must know which size of the product you want to test. So, before you send a inquiry email, please carefully understand the size of the product being tested.

A. The dimension of the test specimen is basic including width, height, deepth, or you use the length, width, height.

B. The outer dimension of climatic test chamber is important too. You need to know how much space you have prepared for putting it in your company or your laboratory.

C. The unit of the dimension of test specimen is also important. For example, some manufacturers would like to use mm, but the other ones maybe like to use feet

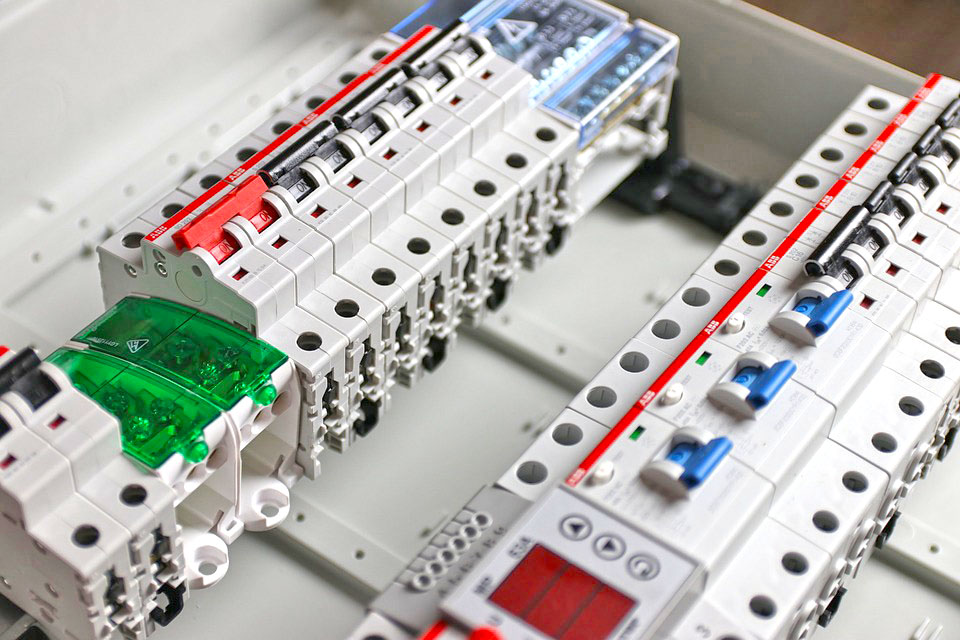

Power Supply Safety Protection is the important component of the climatic test chamber:

A. Power requirements are determined by your facility’s electrical supply or output, the power supply is 220V 50HZ 4.3KW or 380V 50HZ 3.5KW, you should confirm it carefully with the supplier.

B. Please confirm the power supply system, because some supplier may provide 3 phase 3 wire power supply, but at some countries, they only allow the 3 phase 4 wire power supply system.

C. Please confirm with the manufacturers the ground wire is installed or not, meanwhile, you could confirm the ground wire is reliable connected the ground. If not, maybe the operator will get an electric shock

Whatever you want to purchase any type climatic test chamber, the purchase budget is the important consideration.

A. At the first, the climatic test chamber price, you must need to confirm with manufacturers the price is EXW, FOB or CIF. The EXW price is basic climatic test chamber price, the CIF price is including the freight. Specific price details, you could communicate with the suppliers.

B. Then you need to confirm what payment method and currency unit you want to choose. For example, most companies like the T/T payment method and USD unit.

C. The last but not least, you must confirm the after-sales service period, some companies is one year and other one is two years

STS provides supporting after-sales service for every cooperation company with us. STS could provide online real-time after-sales service, if you have any problems about the ordered climatic test chamber

Sealing test space could ensure the test results are accurate; Uniformed designed air outlets secure the eveness of airflow influencing the test conditions uniformity; various sealing ways ensure sealing of the test space, such as silicone plug, silicone sealing strip and etc,.

We will contact you within 1 working day, please pay attention to the email with the suffix “@ststestchamber.com”.