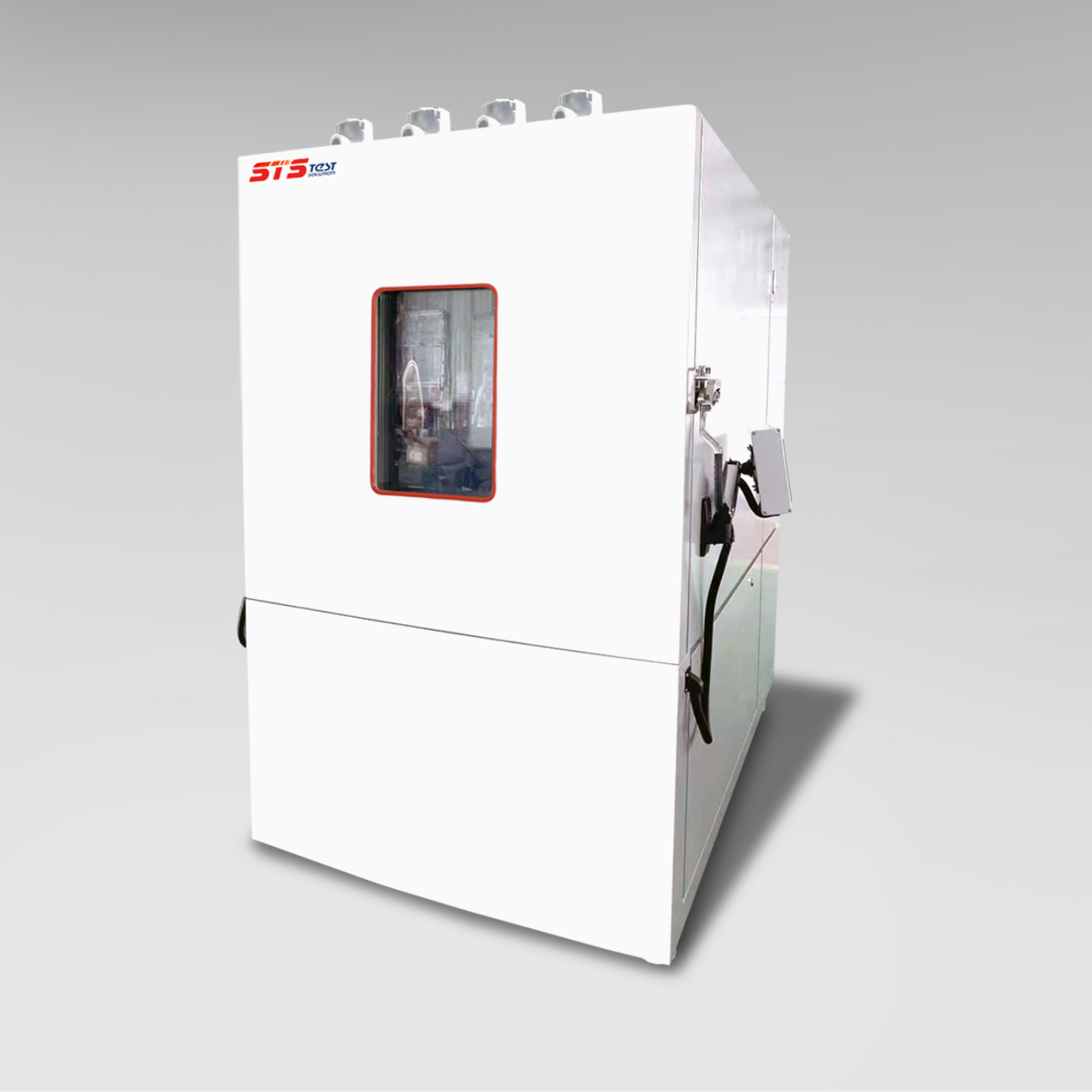

The mixed gas corrosion test chamber is widely used in aerospace, automobile and motorcycle, ordnance, electrical and electronics, chemical metallurgy, quality inspection and measurement, post and telecommunications, ships and railways and other enterprises and institutions, colleges and universities and scientific research units.