Date: May 7th

Weather: Cloudy

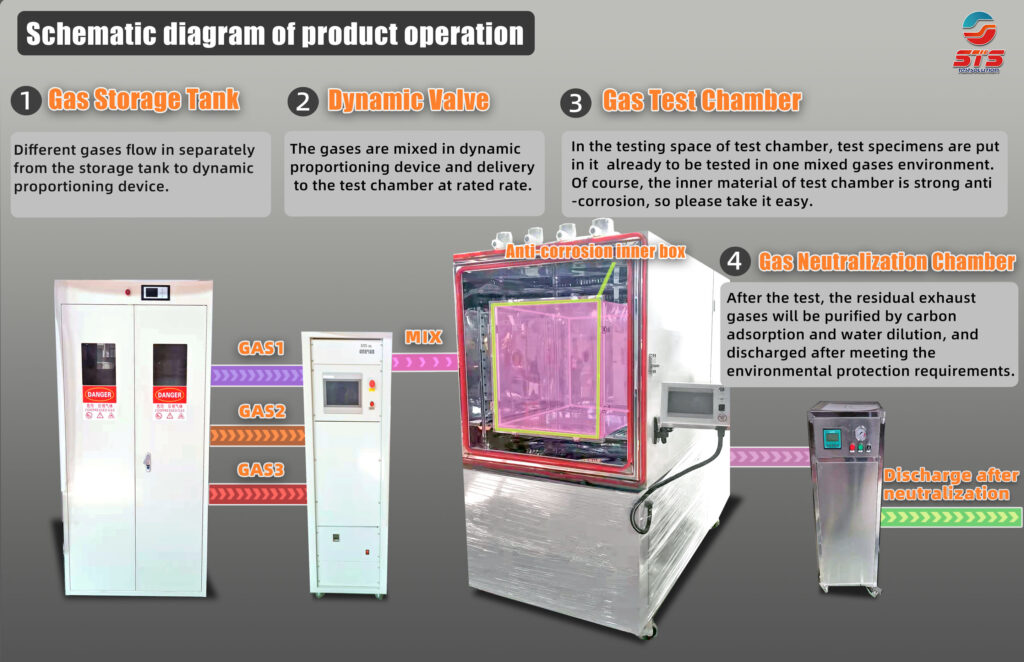

Topic: Gas Corrosion Test Chamber Workflow

Content:

More and more customers are interested in our the Gas Corrosion Test Chamber Workflow at last two months, so we write this short article to answer.

Step 1: Different gases flow in separately from the storage tank to dynamic proportioning device;

Step 2: The gases are mixed in dynamic proportioning device and delivery to the test chamber at rated rate;

Step 3: In the testing space of test chamber, test specimens are put in it already to be tested in one mixed gases environment. Of course, the inner material of test chamber is strong anti-corrosion, so please take it easy.

Step 4: After the test, the residual exhaust gases will be purified by carbon adsorption and water dilution, and discharged after meeting the environmental protection requirements.

To be better understood, the following photo is the Schematic Diagram, you could understand it via it:

Hope every one have nice weekend~