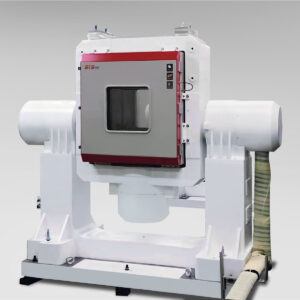

| Model | 360L-40W | 720L-40W | 1000L-40W | 2370L-40W |

Test Space Dimensions(mm) | W(wide) | 600 | 800 | 1000 | 1300 |

| H(high) | 750 | 900 | 1000 | 1300 |

| D(deep) | 800 | 1000 | 1000 | 1400 |

Exterior Housing Dimensions(mm) | W(wide) | 1100 | 1310 | 1510 | 1810 |

| H(high) | 900 | 2050 | 2150 | 2450 |

| D(deep) | 1900 | 2200 | 2200 | 2650 |

Performance | Temperature Range (℃) | (-70~160) ℃ |

| Pressure Range (kPa) | Atmospheric pressure ~ 0.5 |

| Temperature Fluctuation (℃) | ±0.3℃ (when atmospheric pressure) |

| Temperature Deviation (℃) | ±2.0℃ (when atmospheric pressure) |

| Pressure Deviation (kPa) | ≤±0.1kPa(≤2kPa),≤±5kPa(2~40kPa),≤±2kPA(d≥40kPa) |

Heating Up Time | (25~160)℃ ≤60min(when atmospheric pressure) |

| ≤45min (when atmospheric pressure) | ≤60min (when atmospheric pressure) | ≤60min (when atmospheric pressure) | ≤90min (when atmospheric pressure) |

Cooling Time | (Atmospheric pressure~0.1) kPa (dry in atmospheric chamber) |

| ≤20min | ≤25min | ≤30min | ≤45min |

| Quick Pressure Relief | The test chamber is rapidly relieved from 75kPa to 18.8 within 15min (meet the rapid pressure relief function of GJB150.2a) |

| Temperature And Humidity Control Mode | BTCH balance temperature mode |

Material | Inner Box Material | Stainless steel plate SUS304 |

| Outer Box Material | The outer box is made of manganese steel, the surface is sprayed with plastic, and the shell is pressure bearing |

| Insulation | Vacuum special composite pressure insulation material |

| Using The Environment | Temperature:(5~36) ℃, Humidity: (30~85) %RH, Air pressure:(86~106) kPa |

Actuator | Fan | Magnetic coupling drive shaft flow fan |

| Refrigerator | Low noise piston compressor or scroll compressor |

| Heater | Imported nickel-chromium alloy electric heating wire, wall heater |

Controller System | Touch Screen + PLC | 7.0″, 800×480 resolution, mixed output PLC |

| Operation Mode | Constant value operation, program operation, timing operation |

| Setting Method | Simplified Chinese + English, touch input |

| Program Capacity | 96 groups of programs, each group of 102 segments, 9999 cycles can be set, the program has a link function |

| Predetermined Area | According to the maximum range of equipment performance, adjust ±5.0℃ |

| Display Resolution | Temperature: 0.01℃, humidity range: 0.1%RH(humidity device), time: s |

| Sensor | PT100 (platinum resistance) |

| Way To Control | Low temperature cold balance + anti-integral saturation PID + self-tuning |

| Curve Record | With the function of saving data, you can swipe to browse the data and grab pictures on the screen |

| Additional Features | Fault alarm and cause treatment prompt function: timing switch machine, power failure protection, user authority function |

Communication Function | Support RS485, LAN (network port), GPRS (mobile phone) and other communication methods, convenient for remote monitoring, data collection: IBM PC compatible machine, PII or higher CPU, 128M or higher memory, simplified Chinese version of the operating system |

Data Collection | 1.Equipped with a USB interface, it can save 3 months of curve data, and can download historical curves and historical data

2.Can replace the recorder, built-in large storage space, continuous 24 hours of power on can save 3 months of data, sampling time is 1 minute, can replace computer storage, users can export historical data (time optional), generate CSV format file

3.Connect to PC (optional)—record experimental data through computer monitoring software, display curves, and PC can be used as a remote terminal to realize remote monitoring |

| Circulating Water Flow(t/h) | 0.4 | 0.6 | 0.4 | 1.2 |

| Power Supply(V)/(Hz) | AC voltage 380V±38V Frequency 50Hz±0.5Hz Three-phase four-wire + grounding protection |

| Power(kW) | VTL: 15 VTH:8 | VTL: 20 VTH: 10 | VTL: 20 VTH: 10 | VTL: 28 VTH: 18 |

| Standard Configuration | 1 vacuum special electric heating observation window, 1 lamp, 1 multi-action inflatable brake, 1 sample power terminal, 2 sets of sample rack, 1 external pressure test port |

| Safety Device | Leakage switch, motor, compressor, phase sequence, over temperature protection functions |